Cast Iron Gate Pump Fitting by Casting Process

Basic Info

Model No.: HZF-815

Product Description

Model NO.: HZF-815 Material: Iron Surface Treatment: Black Oxide Size: Customized Delivery Date: 15-30 Days Trademark: HZF Specification: SGS/ISO/BV HS Code: 84089452 Standard: DIN, ANSI, GB, JIS, BSW Connection: Flange Head Type: Round Port: Qingdao Port MOQ: 1000 PCS Transport Package: Crate or Plywood Case or as Customers′ Request Origin: Shandong, China Cast Iron Gate Pump Fitting

1. Product Details:

1. Product Name: Investment Casting / Precision Casting Parts / ball Valves / stainless steel Sand Casting Parts / Machinery Parts / CNC Machining Parts, Steel Investment Casting / lost wax / casting / Die Casting

2. Progress of precision casting: Investment casting

3. Precision Casting materials: Stainless steel, Carbon steel,iron, alloy, aluminum

4. We can do different kinds of surface treatment after casting, such as machining, polishing, and plating

5. All sorts of precision casting parts: marine casting parts, auto parts, machinary casting parts, pump parts, hardware parts

6.OEM are welcomed.

We wil be happy to give you our best price upon receipt of your detailed requirements.

Samples are avalaible for quality check.

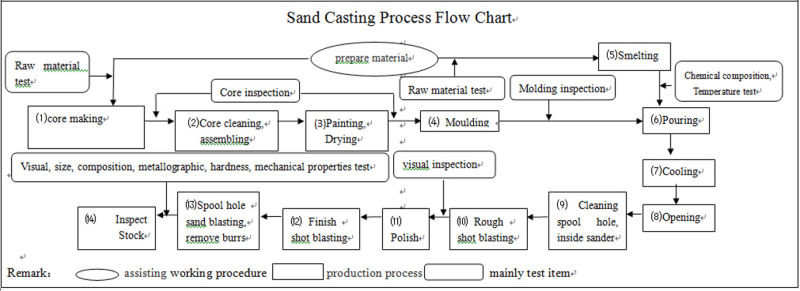

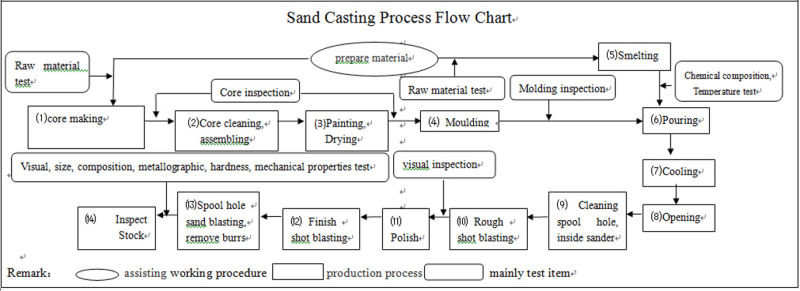

2. Sand Casting Process :

3. Inspection

4. Shipment & Package :

FAQ

1. How can I get the quotation?

Please send us information for quote : drawing, material, weight, quantity and request.

2. How long will be taken for sample production ?

Sample: 20-30 days for making mold and sample production . The accurate time depends on your product.

3. Can you accept Mini order ?

Yes . Mini order and trial order can be acceptable .

4. What is your Payment Term ?

Mold cost : 100% TT advanced.

Main order: 40% deposit, balance 60% to be paid against the copy of B/L .

Contact us Today :

Contact us if you need more details on Fitting. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Pump Fitting、Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Product Details:

1. Product Name: Investment Casting / Precision Casting Parts / ball Valves / stainless steel Sand Casting Parts / Machinery Parts / CNC Machining Parts, Steel Investment Casting / lost wax / casting / Die Casting

2. Progress of precision casting: Investment casting

3. Precision Casting materials: Stainless steel, Carbon steel,iron, alloy, aluminum

4. We can do different kinds of surface treatment after casting, such as machining, polishing, and plating

5. All sorts of precision casting parts: marine casting parts, auto parts, machinary casting parts, pump parts, hardware parts

6.OEM are welcomed.

We wil be happy to give you our best price upon receipt of your detailed requirements.

Samples are avalaible for quality check.

| Item | Typical | Feasible |

| Shapes | Thin-walled: Complex Solid: Cylindrical Solid: Cubic Solid: Complex | Flat Thin-walled: Cylindrical Thin-walled: Cubic |

| Part size | Weight: 1 oz - 450 ton | |

| Materials | Metals Alloy Steel Carbon Steel Cast Iron Stainless Steel Aluminum Copper Magnesium Nickel | Lead Tin Titanium Zinc |

| Surface finish - Ra | 300 - 600 μin | 125 - 2000 μin |

| Tolerance | ± 0.03 in. | ± 0.015 in. |

| Max wall thickness | 0.125 - 5 in. | 0.09 - 40 in. |

| Quantity | 1 - 1000 | 1 - 1000000 |

| Lead time | Days | Hours |

| Advantages | Can produce very large parts Can form complex shapes Many material options Low tooling and equipment cost Scrap can be recycled Short lead time possible | |

| Applications | Gears, pulleys, crankshafts, connecting rods, and propellers; housings for large equipment and heavy machine bases,engine blocks; engine manifolds, cylinder heads, and transmission cases. | |

2. Sand Casting Process :

3. Inspection

4. Shipment & Package :

FAQ

1. How can I get the quotation?

Please send us information for quote : drawing, material, weight, quantity and request.

2. How long will be taken for sample production ?

Sample: 20-30 days for making mold and sample production . The accurate time depends on your product.

3. Can you accept Mini order ?

Yes . Mini order and trial order can be acceptable .

4. What is your Payment Term ?

Mold cost : 100% TT advanced.

Main order: 40% deposit, balance 60% to be paid against the copy of B/L .

Contact us Today :

Contact us if you need more details on Fitting. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Pump Fitting、Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Castings > Sand Casting

Premium Related Products

Other Products

Hot Products

Mirror Bathroom Accessories Polish Brass Die CastingAluminum Sand Casting Investment Casting for Car PartStainless 304 316 CNC Machining Turning Parts for Car PartsLatch for Industrial or Auto Parts Hardware ComponentsCast Iron Garden Chair Leg by Sand Casting ProcessingCast Iron for Hydraulic Cylinder End Caps ClevisSteel Iron Railway Clip Made by Die ForgingStainless Steel Auto Part Cross Coupling by Forged ProcessingStainless Steel Casting Beam Clamp for ConstructionSand Casting Parts for Solar Roof Hook Bolts 150*200Flat Blade Street Name Sign Bracket by Die Casting ProcessingOEM Aluminum Die Casting for LED Light HousingCNC Machining Part for Trailer Ball by ForgingAluminum Die Casting Industry Sewing Machine Series Chassis 2CNC Machining Sleeve and Shaft Used on Auto PartAluminum Die Casting Heavy Duty Truck Oil Water Separator Shell