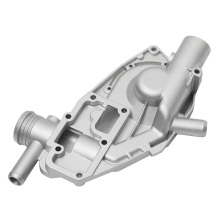

Centrifugal Casting Stator Steel with Fine CNC Machining

Basic Info

Model No.: HZF-804

Product Description

Model NO.: HZF-804 Processing Type: Metal Spinning Mould: Multistep Progressive Dies Fine Blanking: Open Industry: Metal Stamping Parts Customized: Customized Port: Qingdao Color: Silver Transport Package: Crate or Plywood Case or as Customers′ Request Origin: Shandong, China Type: Cold Stamping Material: Stainless Steel Surface Processing: Electroplating Process: Forming Process Tolerances: 0.01mm Delivery Date: 15-30 Days MOQ: 1000PCS Trademark: HZF Specification: SGS/ISO/BV HS Code: 84089452

Key Specifications/Special Features:

Investment casting process describing:

We offer customers two types of investment cast processes

They are the shell process and the water glass process

The shell process is used to cast complex high-quality parts with requirements of a very good surface finish and close dimensional tolerances

The water glass process is typical of the process in the early stages of investment Castings

It generally is capable of much larger castings than the shell process, but does not have as good of surface finish or tolerances

The water glass process provides parts that have better surface finish and dimensional tolerances than sand castings

A wide range of alloys is available for both processes

They include carbon steels, low alloy steels, stainless steels, tool steels and copper based alloys

Other material may be available upon request

Shell investment cast parts can range from a weight of just a few ounces to approximately 50 pounds

If you are concerned with precision in very small parts, we are especially proficient at very fine detail work including teeth and serrations

Water glass castings may range in weight from several ounces to approximately 175 pounds

First article layouts and spectrometer material certifications are provided with all first article samples

A variety of secondary operations can be performed on both types of investment castings

They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging Contact us if you need more details on Stator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Centrifugal、Castings. If these products fail to match your need, please contact us and we would like to provide relevant information.

Key Specifications/Special Features:

| Name | Centrifugal Casting Stator Steel |

| Process | Investment Casting;CNC Machining |

| Materials | cast iron, ductile cast iron, carbon steel, steel alloy, stainless steel, brass, aluminum and zinc alloy |

| Weight | 0.03-20000kgs |

| Usage: | metallurgy, automobile, aero, chemical, ship hardware and Other engineering industry |

Investment casting process describing:

We offer customers two types of investment cast processes

They are the shell process and the water glass process

The shell process is used to cast complex high-quality parts with requirements of a very good surface finish and close dimensional tolerances

The water glass process is typical of the process in the early stages of investment Castings

It generally is capable of much larger castings than the shell process, but does not have as good of surface finish or tolerances

The water glass process provides parts that have better surface finish and dimensional tolerances than sand castings

A wide range of alloys is available for both processes

They include carbon steels, low alloy steels, stainless steels, tool steels and copper based alloys

Other material may be available upon request

Shell investment cast parts can range from a weight of just a few ounces to approximately 50 pounds

If you are concerned with precision in very small parts, we are especially proficient at very fine detail work including teeth and serrations

Water glass castings may range in weight from several ounces to approximately 175 pounds

First article layouts and spectrometer material certifications are provided with all first article samples

A variety of secondary operations can be performed on both types of investment castings

They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging Contact us if you need more details on Stator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Centrifugal、Castings. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : CNC Machining Part

Premium Related Products

Other Products

Hot Products

Mirror Bathroom Accessories Polish Brass Die CastingAluminum Sand Casting Investment Casting for Car PartStainless 304 316 CNC Machining Turning Parts for Car PartsLatch for Industrial or Auto Parts Hardware ComponentsCast Iron Garden Chair Leg by Sand Casting ProcessingCast Iron for Hydraulic Cylinder End Caps ClevisSteel Iron Railway Clip Made by Die ForgingStainless Steel Auto Part Cross Coupling by Forged ProcessingStainless Steel Casting Beam Clamp for ConstructionSand Casting Parts for Solar Roof Hook Bolts 150*200Flat Blade Street Name Sign Bracket by Die Casting ProcessingOEM Aluminum Die Casting for LED Light HousingCNC Machining Part for Trailer Ball by ForgingAluminum Die Casting Industry Sewing Machine Series Chassis 2CNC Machining Sleeve and Shaft Used on Auto PartAluminum Die Casting Heavy Duty Truck Oil Water Separator Shell