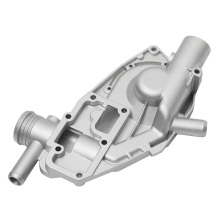

CNC Machining Spare Part for Injection Molding Machine

Basic Info

Model No.: HZF-430

Product Description

Model NO.: HZF-430 Delivery Date: 15-30 Days Trademark: HZF Specification: SGS/ISO/BV HS Code: 84089452 Size: Customized Surface Finish: Customized Transport Package: Crate or Plywood Case or as Customers′ Request Origin: Shandong, China

Key Specifications/Special Features

Inspection:

Inspection: in-house and third party

All the products are strictly inspected by operator and skilled QC with record put down.

Universal inspection tools: three-coordinates measuring machine,hardness tester, Height ruler, Depth ruler, Outside ruler, Venire Caliper, etc.

INTRODUCE:

We Qingdao Haozhifeng Machinery Co.,Ltd, is a leading enterprise, specializing in mechanical parts of torque for bushing with different size and material. Torque rod bushing is mainly used in mechanical system as auto, truck, tractor and so on which demand torque rod bushing spare part. With high metal strength, torque rod bushing works long hours. Coated with kinds of surface treatment of environmental fluid, torque rod bushing obtains strong mechanical properties and resistance to corrosion.

2. Quality Control

1) Material Supply

To be sure material specification and size correct.

To be sure material chemical composition correct, material certification must be provided in each material purchasing lot.

2) Machining Process

Setup work instruction chart for each part.

Check production process and updated drawing issue before machining.

Fixed Inspection: 4 times/shift, have records to check, carried by QC.

Random Inspection: to avoid uncertain potential quality issues.

Final Inspection: Each part have its final inspection stardard before packing, have inspection sheet to track.

3)Packing and Assembly

To meet custom requirements, including labels, cartons, pallets etc before shipment Contact us if you need more details on Spare Part. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Machine Spare Part、CNC Spare Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Key Specifications/Special Features

| Material: | aluminum alloy steel |

| Machining: | CNC turning, milling, drilling and boring |

| Surface treatment: | sandblasted |

| Heat treatment: | normalizing, quenching, tempering and annealing |

| Weight: | 0.2 to 500kg |

| Packing: | seaworthy packing or as per customer's requests |

Inspection:

Inspection: in-house and third party

All the products are strictly inspected by operator and skilled QC with record put down.

Universal inspection tools: three-coordinates measuring machine,hardness tester, Height ruler, Depth ruler, Outside ruler, Venire Caliper, etc.

INTRODUCE:

We Qingdao Haozhifeng Machinery Co.,Ltd, is a leading enterprise, specializing in mechanical parts of torque for bushing with different size and material. Torque rod bushing is mainly used in mechanical system as auto, truck, tractor and so on which demand torque rod bushing spare part. With high metal strength, torque rod bushing works long hours. Coated with kinds of surface treatment of environmental fluid, torque rod bushing obtains strong mechanical properties and resistance to corrosion.

2. Quality Control

1) Material Supply

To be sure material specification and size correct.

To be sure material chemical composition correct, material certification must be provided in each material purchasing lot.

2) Machining Process

Setup work instruction chart for each part.

Check production process and updated drawing issue before machining.

Fixed Inspection: 4 times/shift, have records to check, carried by QC.

Random Inspection: to avoid uncertain potential quality issues.

Final Inspection: Each part have its final inspection stardard before packing, have inspection sheet to track.

3)Packing and Assembly

To meet custom requirements, including labels, cartons, pallets etc before shipment Contact us if you need more details on Spare Part. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Machine Spare Part、CNC Spare Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : CNC Machining Part

Premium Related Products

Other Products

Hot Products

Mirror Bathroom Accessories Polish Brass Die CastingAluminum Sand Casting Investment Casting for Car PartStainless 304 316 CNC Machining Turning Parts for Car PartsLatch for Industrial or Auto Parts Hardware ComponentsCast Iron Garden Chair Leg by Sand Casting ProcessingCast Iron for Hydraulic Cylinder End Caps ClevisSteel Iron Railway Clip Made by Die ForgingStainless Steel Auto Part Cross Coupling by Forged ProcessingStainless Steel Casting Beam Clamp for ConstructionSand Casting Parts for Solar Roof Hook Bolts 150*200Flat Blade Street Name Sign Bracket by Die Casting ProcessingOEM Aluminum Die Casting for LED Light HousingCNC Machining Part for Trailer Ball by ForgingAluminum Die Casting Industry Sewing Machine Series Chassis 2CNC Machining Sleeve and Shaft Used on Auto PartAluminum Die Casting Heavy Duty Truck Oil Water Separator Shell