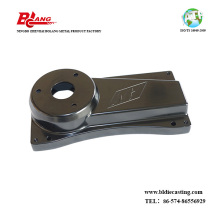

Aluminum Die Casting Parts for Auto

Basic Info

Model No.: HZF-152

Product Description

Model NO.: HZF-152 Die Casting Method: Precision Die Casting Machining: CNC Machining Surface Preparation: Polishing Tolerance Grade: 4 Certification: SGS, CE, RoHS, ISO 9001:2000, ISO 9001:2008 Delivery Date: 15-20 Days Casting Material: Aluminum, Aluminium Alloy Transport Package: Crate or Plywood Case or as Customers′ Request Origin: Shandong, China Die Casting Machine Type: Cold Chamber Die Casting Machine Application: Auto Parts Material: Aluminum Pressure Chamber Structure: Vertical Casting Surface Quality Level: 1 Size: as Customer′s Inquiry Casting Process: Sand Casting, Investment Casting Trademark: HZF Specification: SGS/ISO HS Code: 84807100 Key Specifications/Special Features:

Aluminum Die Casting

Production flow:

Drawings→mould making→raw casting→sandblasting→rough machining or finish machining→surface treatment→product check→packing→delivery strict

About the product

Machining and processing

Heat treatment, polishing, sand blasting, painting, electro-plating, chemical plating, and Other machining processing

Inspection equipments

Spectrum analysis instrument, metallurgical analysis, tensile strength tester, hardness tester, roughness tester, deflection tester, impact test machine, projector, altimeter, scale micrometer, pressure tester and more

Quality control:

(1) Machinery properties and chemical components testing after raw casting

(2) Hardness checking after heat treatment

(3) Dimensions testing after machining

(4) Quality control checks though all the following flow:

Drawings→mould making→raw casting→ sandblasting→rough machining or finish machining→surface treatment→product check→packing→delivery strict

Service

(1) OEM and custom-made service

(2) Full machining, primer painting, and surface treatment

(3) Full material testing process

(4) Quality control

Drawings→mould making→raw casting→ sandblasting→rough machining or finish machining→surface treatment→product check→packing→delivery strict

Our advantage

(1)More 10-years experience in manufacturing and exporting

(2) OEM and custom-made service

(3) All kinds of Castings can be manufactured according to drawing, sample or specific industry standard

(4) Both parts and complete sets can be supplied

(5) Strong engineering team makes high quality

(6) The coordinated service (casting, machining and surface treatment) make lower price possible

(7) Advanced-level equipments

(8) Full material testing process and quality control system

(9) Quality warranty and on time delivery

(10) Two foundries and one machining factory make big order possible Contact us if you need more details on Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Casting、Auto Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.

Aluminum Die Casting

| Casting process: | sand casting, investment casting |

| Casting material: | aluminum, aluminium alloy |

| Standard: | ISO 9001:2008 |

Production flow:

Drawings→mould making→raw casting→sandblasting→rough machining or finish machining→surface treatment→product check→packing→delivery strict

About the product

Machining and processing

Heat treatment, polishing, sand blasting, painting, electro-plating, chemical plating, and Other machining processing

Inspection equipments

Spectrum analysis instrument, metallurgical analysis, tensile strength tester, hardness tester, roughness tester, deflection tester, impact test machine, projector, altimeter, scale micrometer, pressure tester and more

Quality control:

(1) Machinery properties and chemical components testing after raw casting

(2) Hardness checking after heat treatment

(3) Dimensions testing after machining

(4) Quality control checks though all the following flow:

Drawings→mould making→raw casting→ sandblasting→rough machining or finish machining→surface treatment→product check→packing→delivery strict

Service

(1) OEM and custom-made service

(2) Full machining, primer painting, and surface treatment

(3) Full material testing process

(4) Quality control

Drawings→mould making→raw casting→ sandblasting→rough machining or finish machining→surface treatment→product check→packing→delivery strict

Our advantage

(1)More 10-years experience in manufacturing and exporting

(2) OEM and custom-made service

(3) All kinds of Castings can be manufactured according to drawing, sample or specific industry standard

(4) Both parts and complete sets can be supplied

(5) Strong engineering team makes high quality

(6) The coordinated service (casting, machining and surface treatment) make lower price possible

(7) Advanced-level equipments

(8) Full material testing process and quality control system

(9) Quality warranty and on time delivery

(10) Two foundries and one machining factory make big order possible Contact us if you need more details on Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Casting、Auto Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Auto Part

Premium Related Products

Other Products

Hot Products

Mirror Bathroom Accessories Polish Brass Die CastingAluminum Sand Casting Investment Casting for Car PartStainless 304 316 CNC Machining Turning Parts for Car PartsLatch for Industrial or Auto Parts Hardware ComponentsCast Iron Garden Chair Leg by Sand Casting ProcessingCast Iron for Hydraulic Cylinder End Caps ClevisSteel Iron Railway Clip Made by Die ForgingStainless Steel Auto Part Cross Coupling by Forged ProcessingStainless Steel Casting Beam Clamp for ConstructionSand Casting Parts for Solar Roof Hook Bolts 150*200Flat Blade Street Name Sign Bracket by Die Casting ProcessingOEM Aluminum Die Casting for LED Light HousingCNC Machining Part for Trailer Ball by ForgingAluminum Die Casting Industry Sewing Machine Series Chassis 2CNC Machining Sleeve and Shaft Used on Auto PartAluminum Die Casting Heavy Duty Truck Oil Water Separator Shell